Menu

Product categories

Cart

TH745 Telehandler – All Wheel Steer

The multifunctional joystick of the TH745 is a true all-rounder – it controls 16 functions.

Practical for night job sites: the joystick and all of the switches are illuminated.

The cabin of the Wacker Neuson telehandler is very comfortable and highly ergonomic. A comfortable, adjustable seat and practically arranged operator’s controls ensure even more precise work.

Excellent visibility and a low noise level make the TH745 a comfortable place to work. And the telehandler also convinces with an enormous stacking height of 7.017 meters combined with a payload of 4.5 tons.

– Engine speed reduction for lower fuel consumption.

– High performance hydraulics for rapid work cycles.

– 136 PS Deutz engine.

– Ergonomically shaped joystick console.

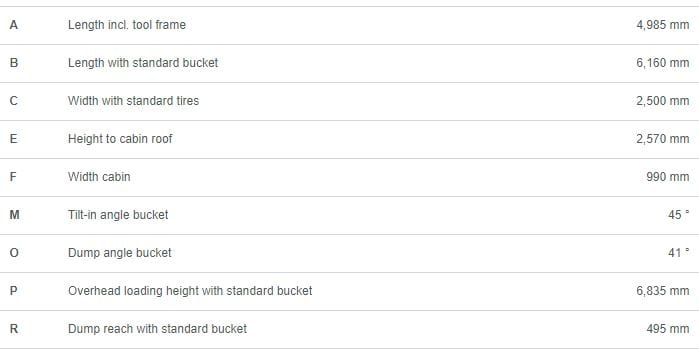

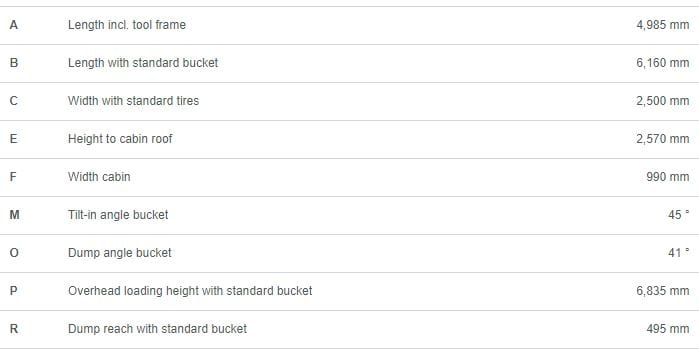

Operating data | |

| Lift height (max.) | 7,017 mm |

| Weight | 9,000 kg |

| Turning radius over tires | 4,240 mm |

Engine / Motor | |

| Engine / Motor manufacturer | Deutz |

| Engine performance | 100 kW |

| Displacement | 3,621 cm³ |

| Emission standards stage | IV |

| Sound emission at the operator ear | 78 dB(A) |

Power transmission | |

| Traction drive | Wide angle hydrostat |

| Speed (standard) | 0–20 km/h |

| Speed (optional) | 0–30 / 0–40 km/h |

| Axles | Planetary-steering drive axle |

| Total pivoting angle | 20 ° |

Steering and operating hydraulics | |

| Duty pump | Load Sensing |

| Flow rate | 140 L/min |

| Pressure | 260 bar |

Kinematics | |

| Bucket capacity | 1.2 m³ |

| Total rotation angle of the vehicle carrier | 150 ° |

| Payload (max. LC 500 mm) | 4,500 kg |

| Lift height at max. payload | 5,100 mm |

| Payload at max. lifting height | 3,300 kg |

| Payload at max. reach | 1,500 kg |

| Range at max. load | 1,600 mm |

| Range (max.) | 3,790 mm |

Filling capacities | |

| Fuel tank capacity | 180 L |

| Hydraulic oil tank | 100 L |

Cabin

The telehandler cabin offers the operator great comfort and a high degree of ergonomics for hours at a time. The adjustable comfort seat and practically arranged operator’s controls permit you to work with even greater precision and functionality. Excellent visibility and low noise level round out the working area.

Ergonomic joystick console

at operator seat: everything under control with just one hand.

Practical for night job sites:

the joystick and all of the switches are illuminated.

Engine and Transmisson

While the engine meets current applicable exhaust emissions standards, it impresses by pairing high performance and economic efficiency:

– Full power and jet economical to use.

– Infinitely variable drive system and perfectly tuned drive train for a given engine size.

– Efficient engine speed reduction to 2000 rpm at maximum speed: The driver selects the travel speed via the pedal. When the maximum speed is reached, the engine speed drops automatically.

ecospeed

– Continuously variable hydrostatic overdrive gearbox for maximum economy and environmental compatibility.

– Direct acceleration without shifting from 0 to 40km/h as well as smooth direction changes minimize fuel consumption and reduce noise emissions.

Hydraulics and Control Circuits

The telehandler impresses by offering powerful work hydraulics with up to 140 L/min.

Besides the rapid loading system work cycles, the hydraulic pumps guarantee operation of special attachments via the 2nd and 3rd control circuit – if needed, even with permanent function.

The telehandler can be equipped optionally with even more control circuits that expand the range of applications.

Three Types of Steering

Whether driving en route or for tight maneuvers: The telescopic loader from Wacker Neuson shows what it is capable of with every job. Thanks to the three different steering modes, it makes the handling of materials a breeze.

All-wheel steering:

particularly maneuverable due to its 2 x 38 degree steering angle.

Front axle steering:

familiar handling even when driving fast on the road.

Crab steering:

ideal for parallel travel and maneuvering in the tightest spaces.

VLS driver assistance system

Work efficiently in complete safety — with the Vertical Lift System (VLS) driver assistance, you will master this challenge with ease. The steady and rapid lowering of the telescopic arm with simultaneous semi-automatic telescoping movement allows even less experienced drivers a smooth operation. The almost vertical lifting and lowering movement also makes the telescopic loader very stable.

Conventional systems (without VLS)

The machines can be pushed to their tip limits purely when lowering.

Driver assistance system VLS

Virtually vertical movement. Hardly any load torque shift in the longitudinal direction of the machine.

Operating input

Loading system response

Telehandler expertise providing benefits.

High payloads

Our telehandlers are designed for performance. They assure you rapid and high materials handling capacity during each use.

Our telehandlers are designed for performance. They assure you rapid and high materials handling capacity during each use.

Work safer than ever

Safe, comfortable and efficient at the same time: In the event, for example, of a risk of overload, the innovative driver assistance system VLS (Vertical Lift System) switches on semi-automatically, intelligently intervening in the telescoping motion, and moving the load downwards in a vertical line.

Safe, comfortable and efficient at the same time: In the event, for example, of a risk of overload, the innovative driver assistance system VLS (Vertical Lift System) switches on semi-automatically, intelligently intervening in the telescoping motion, and moving the load downwards in a vertical line.

More visibility, greater safety

You benefit from improved handling and greater safety while working thanks to optimal view of the attachment and work environment.

You benefit from improved handling and greater safety while working thanks to optimal view of the attachment and work environment.

Locate telehandlers at any time

With the Global Monitoring System, you can always determine the exact location of your machines.

With the Global Monitoring System, you can always determine the exact location of your machines.

Small turning radius, big power output.

The highly maneuverable telehandlers let you turn on a dime, thus giving you ideal maneuverability on the tightest job sites.

Ecological and economical

We distinguish particularly economical and environment-friendly products, such as the telehandler with VLS, by labelling them with an ECO seal.

We distinguish particularly economical and environment-friendly products, such as the telehandler with VLS, by labelling them with an ECO seal.